International Transport Packaging: A Primer

Congratulations. You’ve landed your first overseas sale. Maybe you produce industrial equipment, or large commercial goods that need to be crated. You’re familiar with how to ship your goods around the U.S. But what do you need to know when your products or equipment are going overseas?

International transport packaging is more complicated than domestic transport packaging. And we’d like to help you navigate the requirements so that you can ensure your product can move around the globe without incident. Here’s what you need to know.

- Export Lumber Requirements

For international transport packaging, all dimensional lumber must be ISPM-15 certified. This means you need to work with a packaging manufacturer who can certify the wood this way. Why, you ask?The ISPM-15 stamp, otherwise known as the “bug stamp”, or “wheat stamp” is a stamp that is applied to all packaging kits constructed with solid wood lumber products that have been treated in accordance with the requirements of an international convention that protects plants. Sending untreated wood products overseas can introduce the bugs in those wood products to other countries to wreak havoc on plants on other continents. So the International Plant Protection Convention or IPPC has implemented standards for treatment (heat treating or Methyl Bromide fumigation) that ensures no bugs travel in the wood. Lumber suppliers and packagers learn these requirements well, and make sure that the lumber adheres to the rules and that the stamps are visible at port.

If you don’t have the ISPM-15 stamp on both sides of your wooden crate, then it might get rejected at the port, resulting in huge costs and delays.

- Container travel by sea presents its own challenges.

Most international transport packaging happens by container ship. In domestic travel, you can be sure that the products are shipped by truck and rail. Shipment by sea presents a whole host of new challenges that you have to account for in the packaging process.- Extreme temperature and humidity conditions

Sea travel presents more extreme temperature and humidity conditions, as well as drastic fluctuations in these extremes. The long duration of travel makes these conditions even more problematic. The extreme temperatures and humidity can cause all kinds of problems for your shipment, including container rain, corrosion due to humidity, and structural problems due to moisture (to both the product and the package).A good international transport packager will protect against the elements with desiccant, vapor barrier bags, and added structural support to the packaging. Read here about how to protect against container rain.

- Breakage

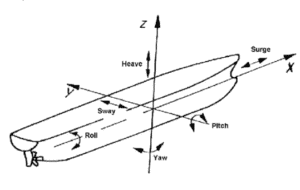

Shipment by sea can expose your package to all kinds risks of damage. First of all, all ocean travel is multi-node travel, because getting the package to and from port requires using other modes of transport. Port standards at your home port might be different than those at the destination port, and the shipment may be handled more roughly, or by different machines.Second, ocean travel exposes your shipment to more forces. In train, truck and air travel, you can account for what forces will wear on the package – horizontal, vertical, tilting, and vibration (air travel includes concerns about air pressure—or lack thereof). Ocean vessels expose your shipment to six types of movement simultaneously – surge, sway, heave, yaw, roll and pitch. This is what causes sea sickness!

ships move in six directions at once To protect your shipment:

-

o be sure to distribute weight evenly

o brace and block shipments with experienced shippers

o clearly and securely label all packages (more on that below)

- Extreme temperature and humidity conditions

- Labeling Concerns

When you send something to a city 100 miles away, they can always call you when the shipment arrives and get clarification of its contents, or some advice about how to unpack it, or advice about where and how to store it.When you send something to the other side of the world, you have to make sure the package speaks for itself. Consider these tips:

- Include labels, whenever possible, in the language of the destination port. Be sure that the labels will not fade or be damaged in the extreme conditions described above.

- Maintain a level of confidentiality. It is best not to put brand labeling on packages in order to prevent pilfering.

- Discuss labeling conventions at length with the buyer, so that you can agree on everything and there are no surprises. Make sure you have a record of the agreement, as travel times can make memories less reliable!

Go ahead and close the sale to that overseas client. Now you know some of the biggest challenges involved in overseas shipments. Get in touch with Reid Packaging to make sure that your shipment gets from here to there without any surprises. At Reid, we have extensive experience working on international transport packaging for industrial, mil spec, and consumer goods. We’ll be happy to quote you a custom job, whether it’s for one crate or 500.