Concealed Damage in Industrial Packaging: How to Diagnose and Prevent It – Part 1 – RFID tags

Freight damage is a perennial problem in the shipping industry, with blame, claims, and headaches affecting everyone from manufacturers to shippers to end users. And freight damage isn’t just inconvenient, it has a ripple effect through the supply chain. It is estimated that 2 to 11% of cargo arrives with some kind of damage, costing as much as $50 billion worldwide each year. Companies that work to minimize cargo damage in this environment have a competitive advantage in the market, reducing costs and supply chain blockages.

We’ve discussed various types of damage in the past, from causes such as moisture, vibration, the over-use of foam, and more. Today we’re focusing on a particularly difficult form of cargo damage: concealed damage.

Concealed Damage

A crate arrives at its destination looking fine, so you sign off on it. But then when you open the crate, the item inside is damaged. This is concealed damage. And it’s a particularly thorny form of cargo damage because it is hard to prove how the damage occurred. Who’s to say where and when the freight was damaged? Is the carrier responsible? Couldn’t the damage have been caused by the consignee after the crate was opened, or what if the item was damaged before it was packaged? These things can be hard to prove, and thus it’s difficult to hold the carrier liable in these cases, leaving you in a tough spot, with a big bill to cover. What’s to be done?

In this article we’ll discuss one of the more technically advanced ways of diagnosing concealed damage using RFID tags. Stay tuned for Part 2 in which we discuss other strategies using single-use shock and tilt indicators.

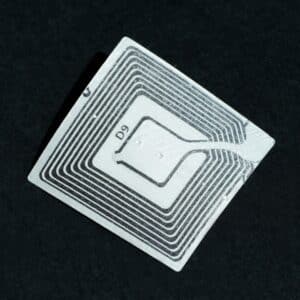

What are RFID tags?

Radio-Frequency Identification or RFID tags are small, thin circuits that you have probably already seen attached to products or packaging. They use electromagnetic fields to automatically identify and track whatever freight they are attached to or embedded in, as they broadcast tracking data to nearby RFID readers. Unlike barcode readers, which have to be pointed directly at each tag, RFID readers only need to be in a relative proximity to the tags in order to scan them, making it very easy to inventory shipments. This minimizes issues of loss and process errors in the supply chain. RFID tags can also help you spot where shipping delays are occurring, helping you construct faster, better routes for your freight.

Passive RFID tags are smaller and less-expensive than active (battery powered) ones, but have a more limited range in terms of connectivity. Passive RFID tags are more common in the healthcare, manufacturing and retail industries, whereas you’re more likely to be see active tags in the oil, gas, construction and mining industries.

RFID tags and concealed damage

RFID tags can contain a plethora of information about your freight. They can contain invoicing and bill of lading data, making tracking much easier, but that is far from all: in cases of concealed damage, RFID tags can let you know what happened to the freight, where it occurred, and when it occurred.

Many RFID tags have tilt, shock and impact recorders, which can tell you if the freight has experienced any drops or falls that may have been responsible for damage. Using GPS tags, they can even tell you when and where along the route these drops occurred, so you know which carrier mishandled your package.

Temperature monitors are another useful feature when claiming concealed damage. For example, if perishable items like food products arrive spoiled, you can refer to RFID tags to determine where along the route the items were exposed to inhospitable temperatures. Humidity monitors are similar. Perhaps your package sat in the rain for several hours before being loaded — RFID tags can tell you where and when this happened.

Concealed damage is a fact of life – here’s what you can do about it

RFID tags are a very useful tool in clearing up some of the blame game that happens in cases of concealed damage, but that doesn’t mean they can prevent it. Let’s face it: concealed damage is going to happen. In addition to using RFID tags, here are some things you can do to minimize the headaches concealed damage is known for causing:

- Always inspect your package prior to signing the POD (Proof of delivery). If you sign a POD, the law assumes that the package was delivered in good condition. If it was not and you signed anyway, your claim becomes harder to prove.

- Take photographs of the damaged package upon receipt. The more documentation you have, the better. If your driver is in a hurry, sign your POD with “pending further inspection”.

- Report the damage as soon as possible, and report it directly to the carrier yourself, rather than relying on the driver. NMFTA recommends you report instances of concealed damage less than five days after the receipt of your freight. The longer you wait to report it, the harder it will be to make your case.

- Purchasing third party insurance for your freight will greatly increase your chances of getting a full payout for your damaged items.

Be proactive

Another thing to consider when thinking about concealed damage is how to prevent it from occurring in the first place. Outfitting your cargo with appropriate insulation, moisture protection, blocking and bracing can help minimize potential environmental stresses and shocks. You can read our guide to effective blocking and bracing here.

Get In Touch to Protect Your Cargo

If you have any more questions about how RFID tags can help you streamline your route and protect your freight, or how to minimize concealed damage, please don’t hesitate to get in touch.