Concealed Damage in Industrial Shipping.Part 2: Single-Use Indicators for Shock, Tilt and Humidity

In a previous article, we discussed the problem of concealed damage in industrial shipping. This is when the damage that a product has sustained is not visible from the packaging, or from a first look at the product. Concealed damage is a serious problem in industrial shipping and can lead to headaches as it is difficult to determine who has liability. Having strategies to combat concealed damage is of the utmost importance when you’re packing and shipping industrial goods.

In Part 1 of this article, we discussed one solution: RFID tags. These are a high-tech way to track your goods and see if they had any damage sustained during shipment. RFIDs are a small circuit that you attach to the item which can track shocks and problems in shipment, as well as giving geographical data about where the damage occurred. While effective, RFID tags can come with a heftier price tag.

In Part 2, we will discuss some other solutions that are inexpensive and less high-tech. These are single-use indicators for shock, tilt and humidity. As always, let us know if you have any questions.

What Are Single-Use Shock Indicators?

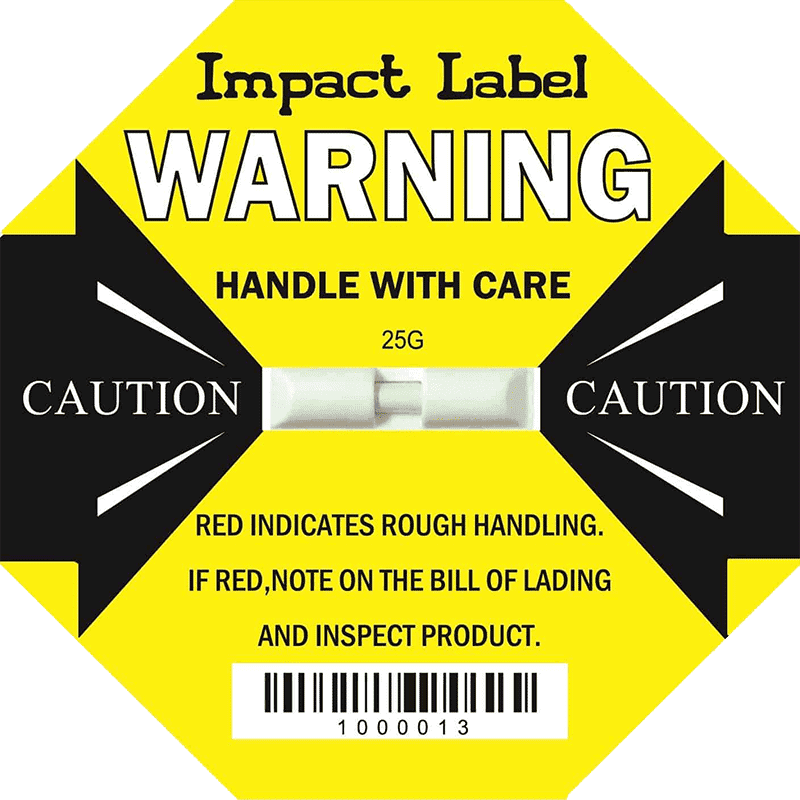

Single-use shock indicators are a great way to protect against concealed damage and the liability that comes with it. These are small, inexpensive indicators that you stick onto a product or package during its shipment journey. The sticker holds a small tube with liquid suspended inside. The tube and the liquid are engineered to be sensitive to “shock”, which is measured in G-force. Shock is any force that disrupts the package – from a drop, a stop or start, or a hit. If the shock is greater than the intensity it is engineered for, then the liquid will be released in the tube, staining it irrevocably and giving proof that the product sustained an inappropriate shock. This way, when the package arrives at its destination the recipient can determine if the product sustained shock during its journey, even if there is no visible damage.

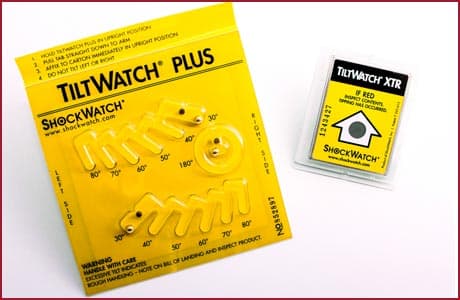

Single-use tilt indicators are small, inexpensive stickers that help protect against inappropriate tilts for your products in shipment. They have small metal balls in them. The balls are suspended in plastic tubes at different angles on the sticker. When the product that the indicator is attached to gets tilted, the ball is able to move down the angled tube and gets stuck in a different position. With the ball in this position, there is proof that the shipment sustained an inappropriate tilt.

Tilt indicators can show tilts of 5 to 80 degrees, and can also indicate if a product was turned upside down. They can also indicate if the tilt was to the right or the left. If a product will be damaged from tilt, then adding tilt indicators to the shipment can ensure that the product is handled appropriately, and, when it is not, that liability for the damage is more clearly attributed.

What Are Single-Use Humidity Indicators?

In addition to tilt and shock, humidity can have a deleterious effect on your shipment. We have discussed this extensively in other articles. If your shipment is exposed to a humid environment for a long time, it can cause concealed damage to the product, including corrosion, discoloration, structural damage and more. A single-use humidity indicator can be attached to the shipment and show the humidity range it sustained during shipment. Often, these are used by shipping companies to determine if they need to add desiccant, but they can also be used by the manufacturer to ensure that the shipment is exposed to only appropriate levels of humidity.

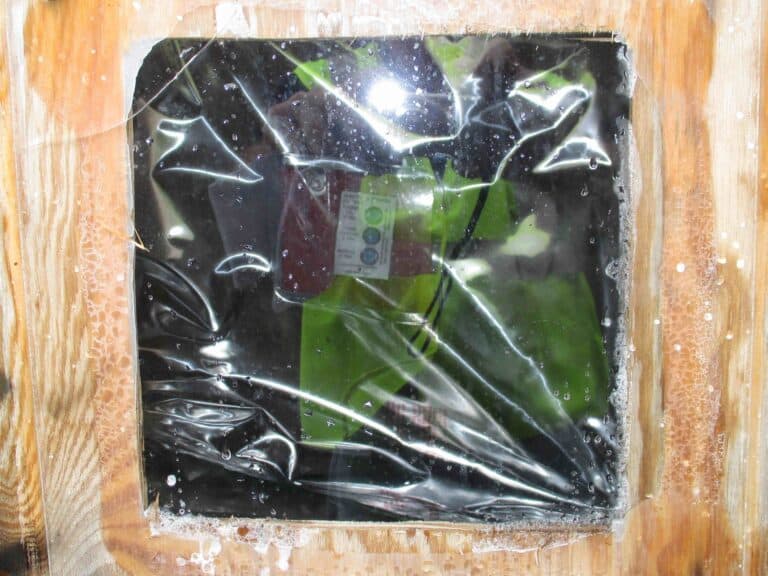

Often, we create a “window” of translucent plastic in a vapor barrier bag so that the humidity indicator is visible to the outside. This allows shippers and manufacturers to monitor the vapor barrier bag to see if there has been a possible rupture in the bag, or if there is not enough desiccant in the bag. Using a humidity indicator inside a vapor-barrier-sealed bag is a great way to have the constant ability to monitor the humidity around your product and make any adjustments if the humidity reaches a dangerous level.

Nothing Unexpected and Unattributable

At Reid Packaging, we’re committed to getting your valuable products from point A to point B safely. Our packages are designed to withstand normal shocks, vibrations, tilts and moisture exposure associated with long shipment journeys. But if you are worried about the mishandling of your products by a carrier, and you need to know if a product might have concealed damage, let us know and we can add inexpensive indicators to the package so that you can be sure they have been handled correctly, and you can hold carriers liable if they mishandle your shipment. As always, we’ve learned a thing or two about industrial packaging over our decades of experience, and we’re happy to discuss your particular request. Get in touch!